Basic Part Manipulation

This section lets you become familiar with a few keyboard functions and with using some of the basic part manipulation tools in the tool palette.

Lesson 1 - Layers

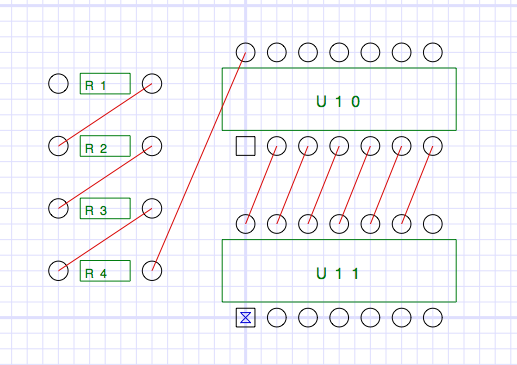

Open the Osmond document Sample1 in the usual way, either by double clicking it, or if Osmond is already running, by selecting it with the Open... command in the File menu. A new window should appear with a simple design as shown below. This design has four resistors (R1, R2, R3, R4) and two 14 pin DIPs (U10, U11). Some of the pads have connecting paths, represented as red lines.

For a nicer view, go to the View menu and turn on Full Width Traces, Solid Pads, and Show Holes. The result should look like this:

The current layer is Layer 1. To go to Layer 2, press the 2 key on the keyboard. Don't hold down the command key or any other modifier key, just press 2.

As you can see, Layer 2 is similar to Layer 1 but has no connecting paths. This is a four layer board so you can also go to Layer 3 and Layer 4 by pressing the 3 and 4 keys on the keyboard. Try this now.

The other way to visit different layers is to click on one of the layer buttons at the bottom left corner of the window.

The layer buttons let you go to Layer 1 through Layer 4 but also let you visit the two Auxiliary layers (A1, A2), the front and back Silkscreen layers (S1, S2), and the front and back Soldermask layers (M1, M2). Try going to different layers with the layer buttons.

To continue with the next lesson, return to Layer 1.

Lesson 2 - Zoom Tool

The tool palette is the group of buttons at the top of the window. Without clicking the mouse, hover the cursor over each of the buttons in the tool palette.

As you hover the cursor over each tool, a short description of the function of the tool appears as a tool tip. Many of the tools can be selected by pressing a single key on the keyboard as described in the documentation. As you become a power user, you will come to appreciate this feature. However, the normal way to select a tool is to click on the tool button. Let us begin the tools lesson by clicking on the Zoom View button.

![]() Note that the cursor now looks like a magnifying glass with a plus in the middle.

Note that the cursor now looks like a magnifying glass with a plus in the middle.

Try clicking near R1. You will see that the view is magnified.

![]() Now hold down the shift or the option key. The cursor now looks like a magnifying glass with a minus in the middle.

Now hold down the shift or the option key. The cursor now looks like a magnifying glass with a minus in the middle.

With the shift key held down, click near R4. The view is now de-magnified to its original size.

You can also use this tool by clicking and dragging through an area. When you release the drag, the magnification changes such that the area selected now fills the screen.

Try using this tool repeatedly to achieve very high magnification. With sufficiently high magnification you will need to use the scroll bars to view different parts of the design.

To continue with the next lesson, go to a magnification that lets you see all the components at once.

Lesson 3 - Select/Move Tool

Click on the Select/Move tool.

Click on either the left or right pad of R1 and drag it to a different location. As you drag, an outline of the part follows the cursor. However, the center of the pad always snaps to the nearest grid crossing. When you finish dragging, R1 is redrawn at the new location. Notice that the path connecting R1 with R2 is still connected.

Next, try moving either U10 or U11. Notice that all the paths maintain their connections.

If you move a part and then change your mind, you can undo the operation by selecting the Undo command in the Edit menu. Nearly all tool operations can be undone in this way.

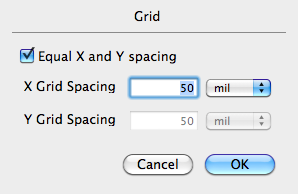

In this first example, the grid is set initially to 50 mil spacing and all pads are at grid crossings. If needed, we can modify the grid to achieve more flexible positioning.

The pads for the resistors are 62 mils in diameter. What if we wanted to put the resistors as close together as possible but still leave 15 mils clearance between the pads. This would require that the distance from the center of one pad to the center of the next pad be 77 mils. Let us make it so.

In the Grid menu, select the Custom... command. This will bring up the grid dialog like this:

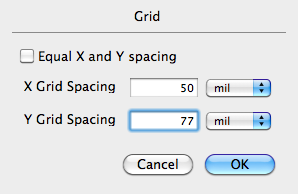

Uncheck the Equal X and Y Spacing button and change the Y spacing to 77 mils. The dialog should now look like this:

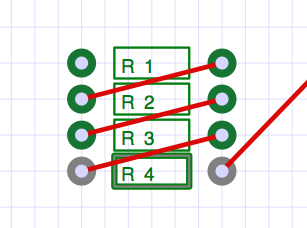

Now move all the resistors so that they are close together and all on grid crossings. The result should look something like this:

For the next lesson, return to an Equal X and Y spacing of 50 mils. Notice that the resistor pads are now off grid.

Lesson 4 - Selecting

If the Select/Move tool is not already selected, click on it now.

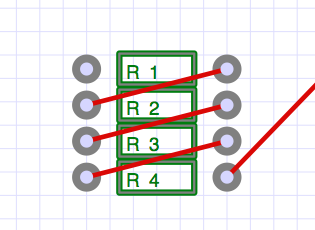

You can use this tool to select one or more components. Try selecting R1 by clicking inside one of its pads. The result should look like this:

Notice that selected parts have their outlines highlighted and their pads grayed. Add R2 to the selection by holding the shift key and clicking inside one of R2's pads.

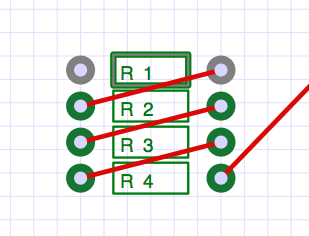

To unselect all parts, click anywhere outside of all pads. Try selecting all the resistors by clicking above all their pads and dragging the selection rectangle so that it contains at least one pad from each resistor. When you release the drag, all resistors should be selected like this:

If you click inside a pad and drag, you will see that all the resistors move as a group.

To continue to the next lesson, use the Select/Move tool to unselect all parts by clicking anywhere on the board, outside of any pad.

Lesson 5 - Turn Tool

Click on the Turn Parts tool.

![]() Notice that the cursor now looks like this to indicate a counter-clockwise direction of rotation.

Notice that the cursor now looks like this to indicate a counter-clockwise direction of rotation.

![]() If you hold down the shift key, the cursor changes to this to indicate a clockwise direction of rotation.

If you hold down the shift key, the cursor changes to this to indicate a clockwise direction of rotation.

To rotate a part, click on one of the pads belonging to the part. The part rotates 90 degrees about the clicked pad in the direction indicated by the cursor.

Try rotating some of the parts both clockwise and counter-clockwise by clicking various pads. Notice that the pad you click is always the center of the rotation and that connecting paths remain connected.

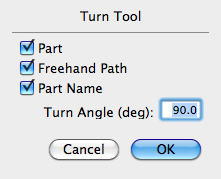

Sometime you may need to rotate a part by an angle other than 90 degrees. To do this, double-click on the Turn Tool in the tool palette to bring up the following dialog:

Try changing the 90 Degree turn angle to 30 degrees (for example) and experiment with rotating parts by the smaller angle.

Using the Select/Move tool that you used in the previous lesson, select all the resistors. Now using the Turn Tool, try to rotate one of the resistors. Notice that all the selected resistors rotate as a group.

Lesson 6 - Flip Tool

Click on the Flip Parts tool.

Parts can either be on the front side of the board or on the back side of the board. Use this tool to flip parts from one side of the board to the other.

Try flipping one of the parts in the design by clicking on its pad. Notice that the color of the part outline changes and that connecting paths remain connected.

The Osmond program will always keep connecting paths connected when flipping parts. For this reason it will not be possible to flip surface mount parts if they already have connecting paths.

This concludes the chapter on manipulating parts. Close the view without saving the design. We will look at a slightly different design in the next chapter.